TOTAL DYNAMIC HEAD

The main components of Total Dynamic Head are:

a) Total Discharge Head, and

b) Total Suction Head.

The equation is:

Total Dynamic Head = Total Discharge Head – Total Suction Head

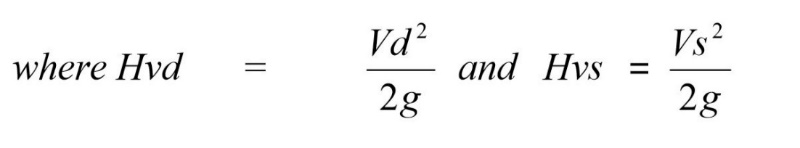

Algebraically, H = (Hd) – (Hs) (m)

or, H = (Hgd + Hvd) – (Hgs + Hvs) (m)

The values Hvd and Hvs are always positive (+ve)

Hd is usually positive (+ve), (above pump centreline)

Hs may be positive (+ve), (above pump centreline) or negative (-ve), (below pump centreline).

When Hs is positive (+ve): H = (Hd) – (Hs) ie: H = Hd – Hs

When Hs is negative (-ve): H = (Hd) – (Hs) ie: H = Hd + Hs

a) Total Discharge Head, Hd

Basic Simple Formula: Hd = Zd + Hfd + Hve (m)

Zd may be positive (+ve) or negative (-ve)

If applicable, additional terms must be included in the formula to account for increased value of Hd, due to any contractions (for example, nozzle friction loss) and enlargements; friction loss in a flow-measuring device and exit into pressure-fed equipment, for example, a hydraulic cyclone.

b) Total Suction Head, Hs

Basic Simple Formula: (Hs) = (Zs) – Hi – Hfs (m)

(Hs) and (Zs) may each be positive, (+ve) or negative (-ve).

If applicable, additional or substitute terms must be included in the formula to account for increased or decreased values of Hs due to any contractions, enlargements, flow measuring device. These are as follows:

- liquid supply surface being under pressure, Hpr, or under vacuum, Hvac;

- ii) differential column head loss, Zc, and

- iii) substitution of effective mixture static suction head Zsm in lieu of Zs.

NOTE: Values of Hs are directly applicable in NPSHa calculations and in selection of shaft-sealing arrangements.

The term “Total Dynamic Head” correctly describes the driving force developed by a centrifugal pump, regardless of the Specific Gravity of the liquid or slurry pumped. The head (+ve) or (-ve) at any point in the system may be converted to pressure or vacuum, respectively, by the application of conversion formulae.

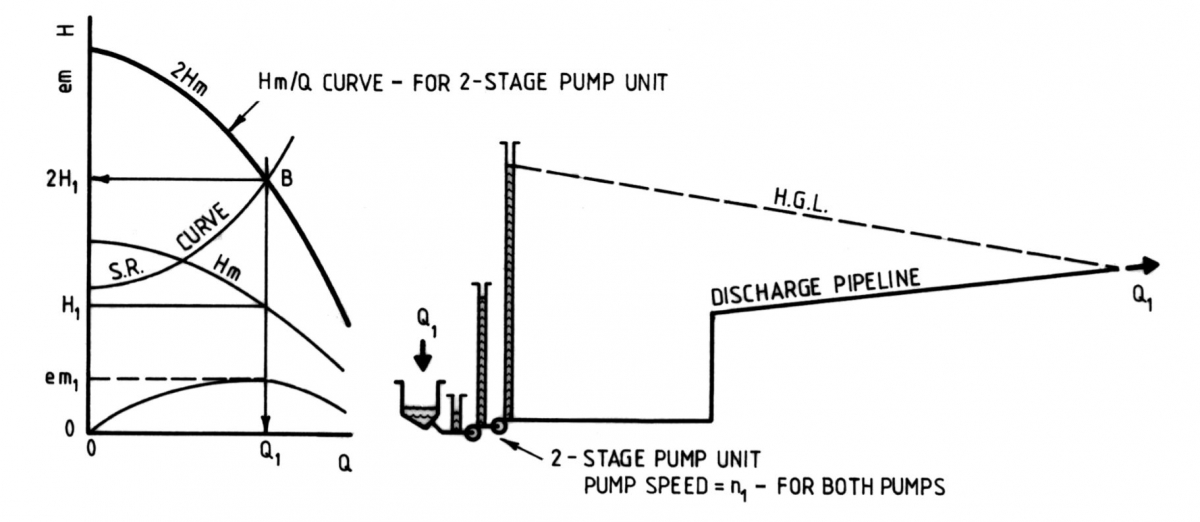

Total Dynamic Head, H, is the head which is required by a given system to maintain a given flow rate, Q, through the system.

H varies as the flow rate through the system, Q, varies. The relationship of H with Q is known as the System Resistance and may be expressed algebraically or graphically.

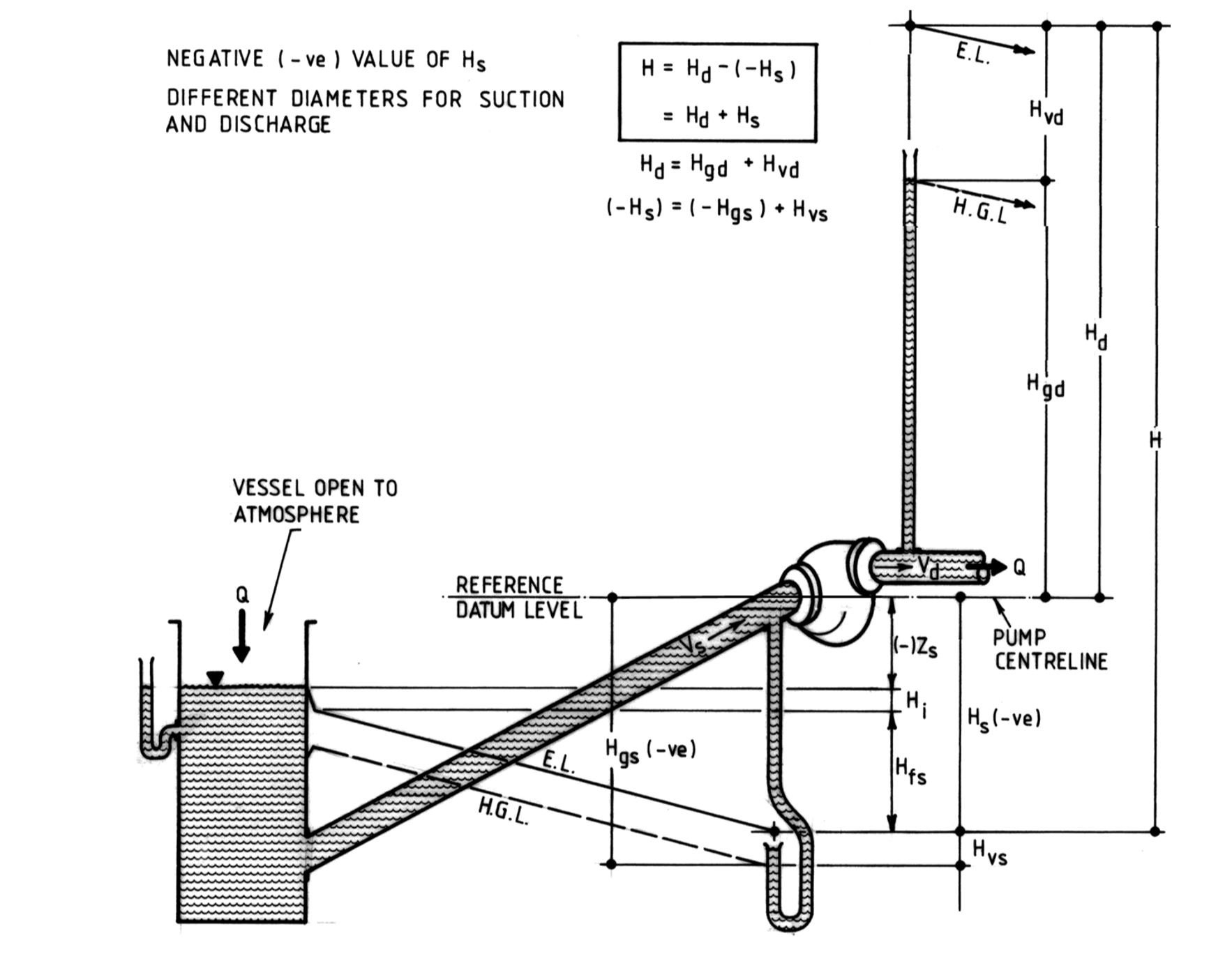

a) Total Dynamic Head: With Positive (+ve) Suction Head

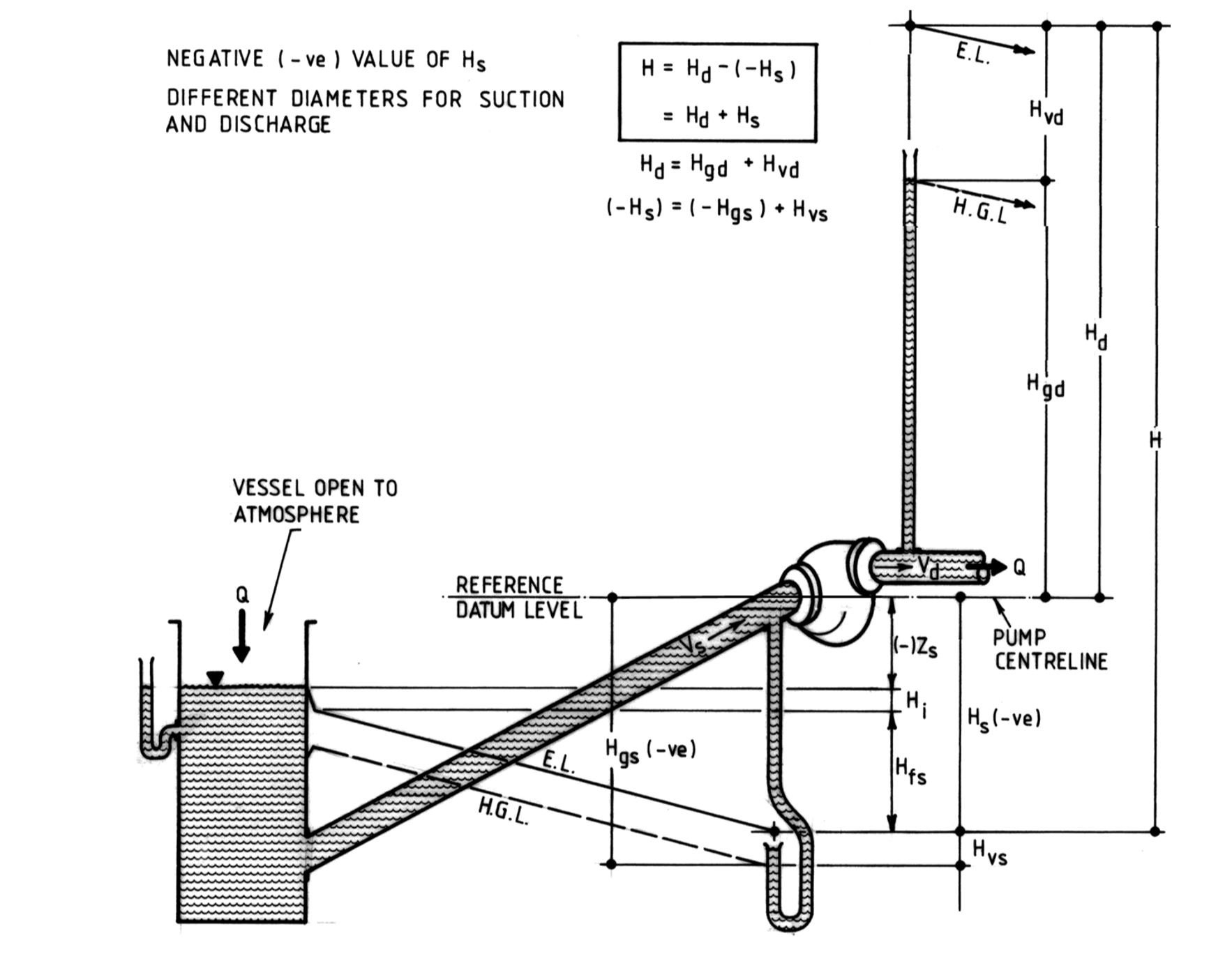

Figure A4-1 illustrates a pump discharging a flow rate, Q, with discharge and suction gauge pressure heads, both relative to atmosphere and both corrected to pump centreline, measured at the pumps discharge flange and at the pump suction flange, respectively. All heads are expressed in metres of actual mixture being pumped.

The Total Dynamic Head, H, required to maintain flow rate Q through the system is the algebraic difference between the Total Discharge Head and the Total Suction Head.

H = Hd – (Hs)

= (Hgd + Hvd) – (Hgs + Hvs)

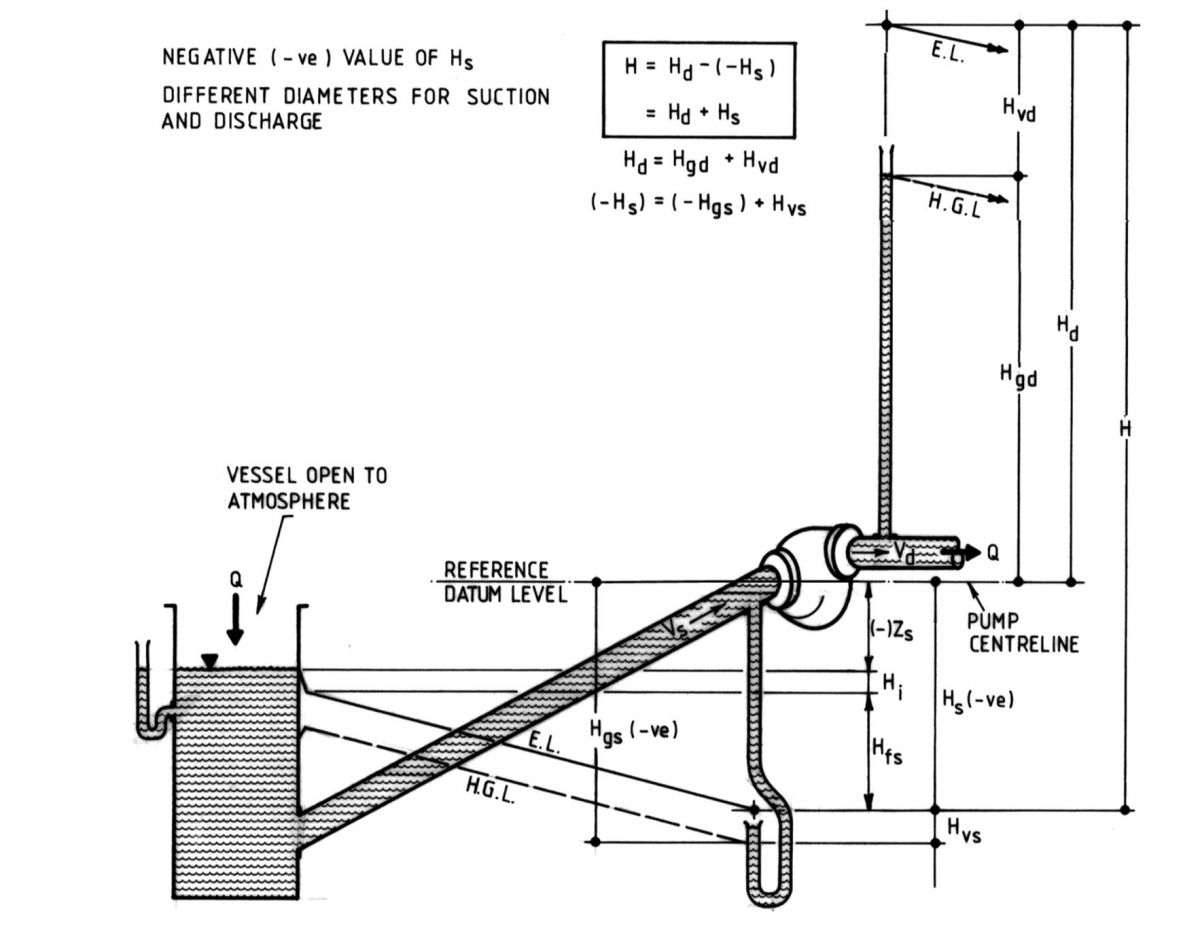

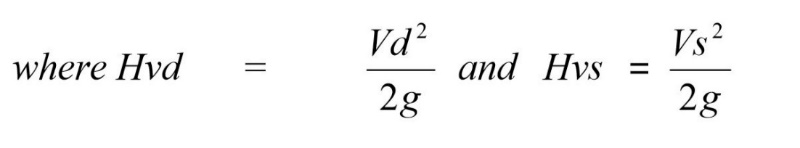

These velocities represent the actual values for average velocity at the pump discharge flange (Vd), and at the pump suction flange (Vs), respectively.

FIGURE A4-1 TOTAL DYNAMIC HEAD WITH POSITIVE INTAKE HEAD

b) Total Dynamic Head: With Negative (-ve) Suction Head

When Hs is negative (-ve) that is, a vacuum head is indicated by the gauge, as in Figure A4-2, the substitution of the negative value in the formula serves to positively increase the value of H with respect to Hd

FIGURE A4-2 TOTAL DYNAMIC HEAD WITH NEGATIVE INTAKE HEAD

As H = (Hd) – (Hs) and as the suction and discharge pipes are often of different internal diameter, it is advisable to estimate values of Hd and Hs separately. The formulae used should be the Basic Simple Formulae, but amended where necessary to allow for any additional or substitute terms specific to the proposed duty as follows:

a) Total Discharge Head: Hd

Basic Simple Formula: Hd = (Zd) + Hfd + Hve

Typical possible additional terms are as follows:

i) Head Loss on conical enlargement (see Figure A4-4);

ii) Head Loss on contraction (see Figure A4-4);

iii) Head Loss on Exit into Pressure-Fed Equipment (refer to Head Loss at Exit into Pressure-Fed Equipment).

b) Total Discharge Head: Hs

Basic Simple Formula: Hs = (Zs) + Hi + Hfs

Typical possible additional terms are as follows:

i) Head GAIN in supply from Pressure Vessel, Hpr;

ii) Head Loss in supply from Vacuum Vessel, Hvac

iii) Head Loss on Differential Column (applicable in dredge applications, Zc – refer to Differential Column Head Loss)

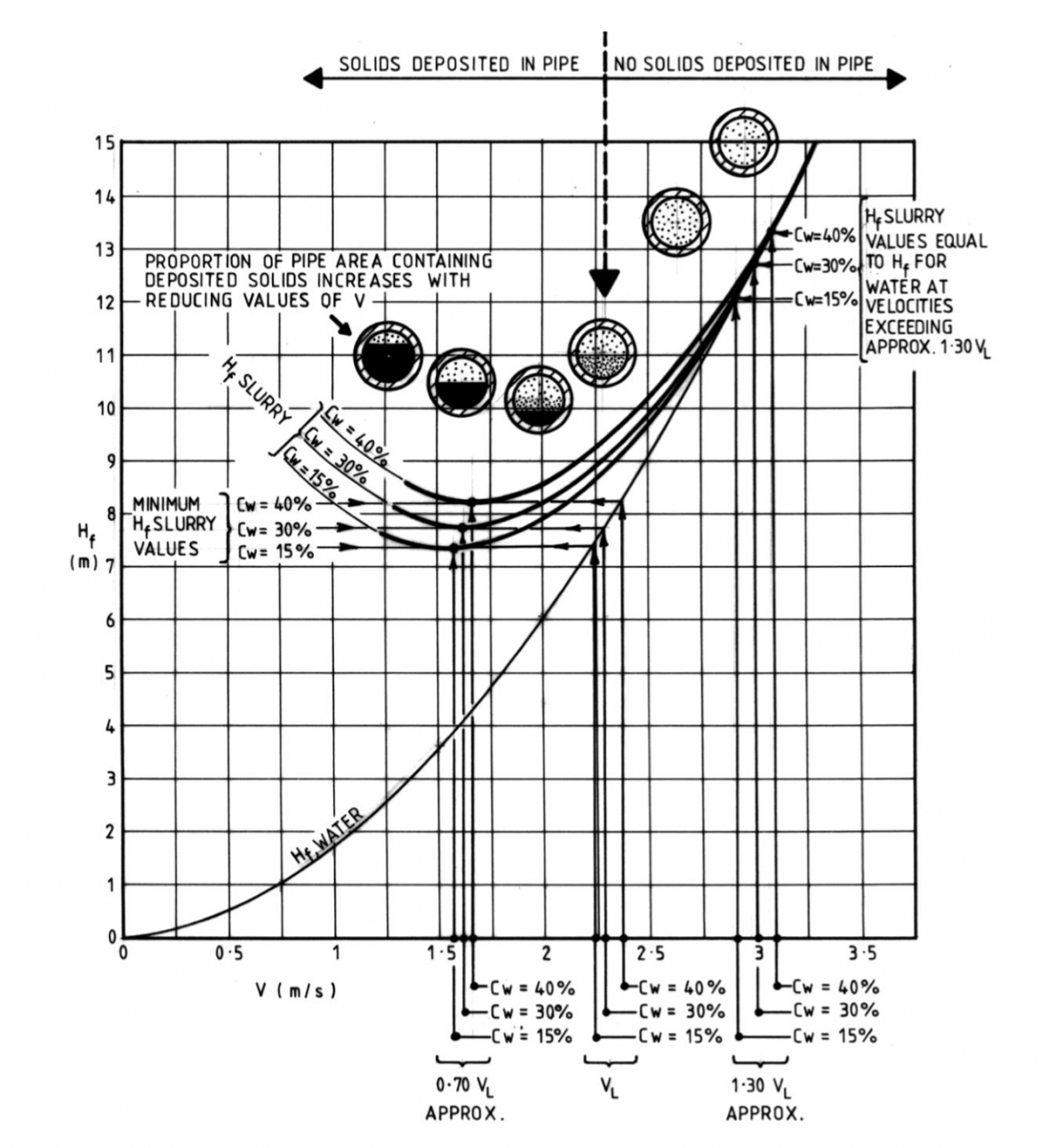

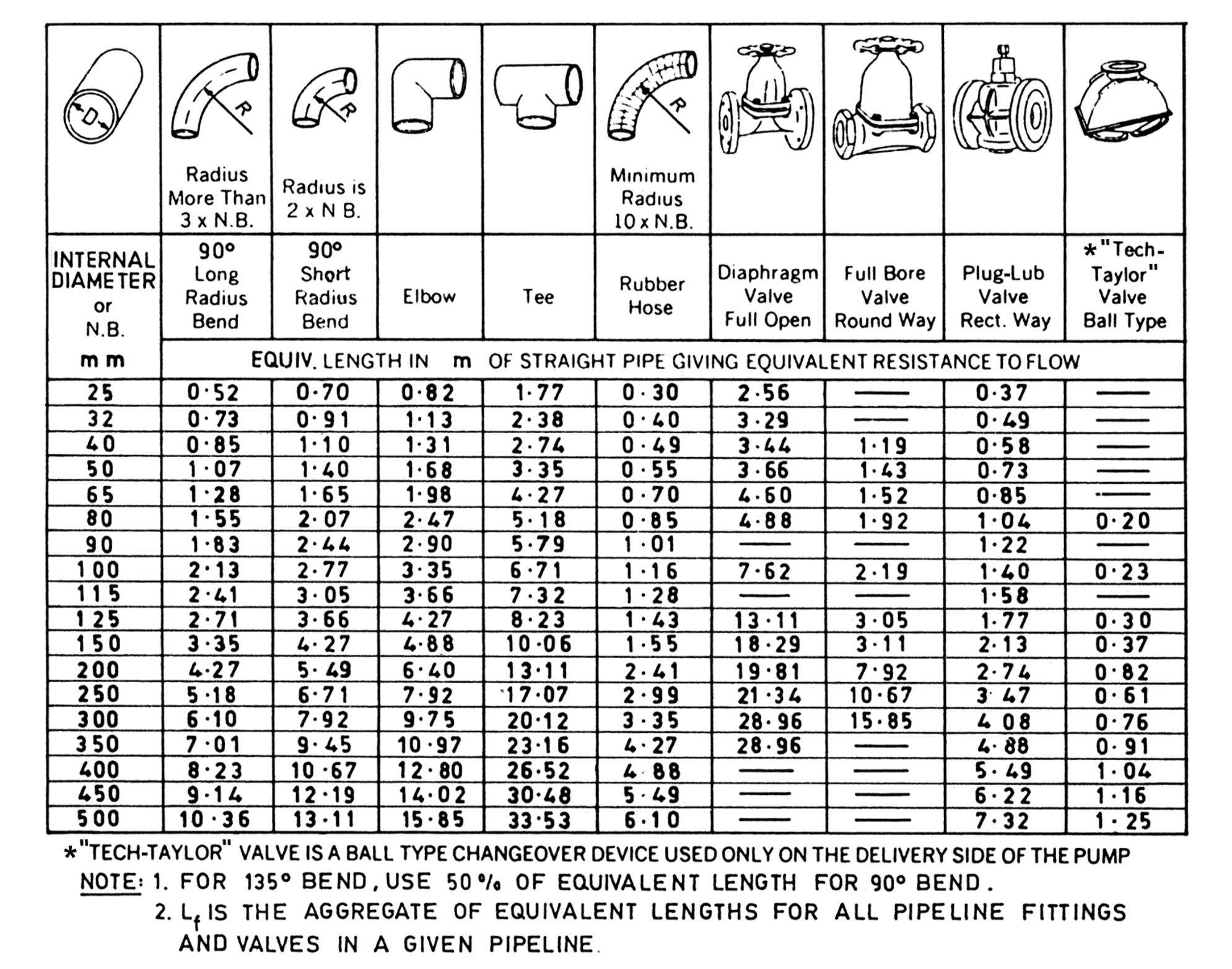

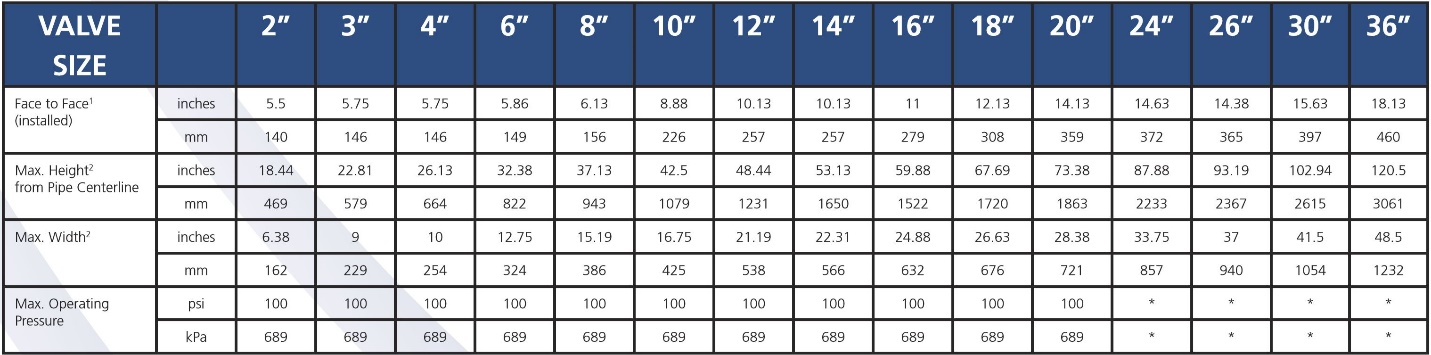

a) Pipeline Friction Head Loss, Hf

The friction head loss in a given pipeline is estimated for the Total Equivalent Length of Pipe, L(m), which is the sum of the Total Actual Length of Pipe, La(m) and the Aggregate of Equivalent Lengths for all valves, bends and like fittings, Lf(m) (see Figure A4-3) contributing to friction head loss in the pipeline.

FIGURE A4-3 EQUIVALENT LENGTHS OF PIPE FITTINGS AND VALVES

Generally L = La + Lf.

Specifically:

i) For Suction Side: Ls = Las + Lfs (Friction Head Loss = Hfs)

ii) For Discharge Side: Ld = Lad + Lfd (Friction Head Loss = Hfd)

Values of Hfs and Hfd should be estimated separately, for example, during the preparation of the respective separate sets of calculations leading to the estimates of Hs and Hd. By separately estimating Hs, its value is readily available for use in NPSHa CALCULATIONS, (refer to APPENDIX 6 – NET POSITIVE SUCTION HEAD (NPSH)), and in the selection of Shaft-Sealing arrangements (refer to Shaft Sealing).

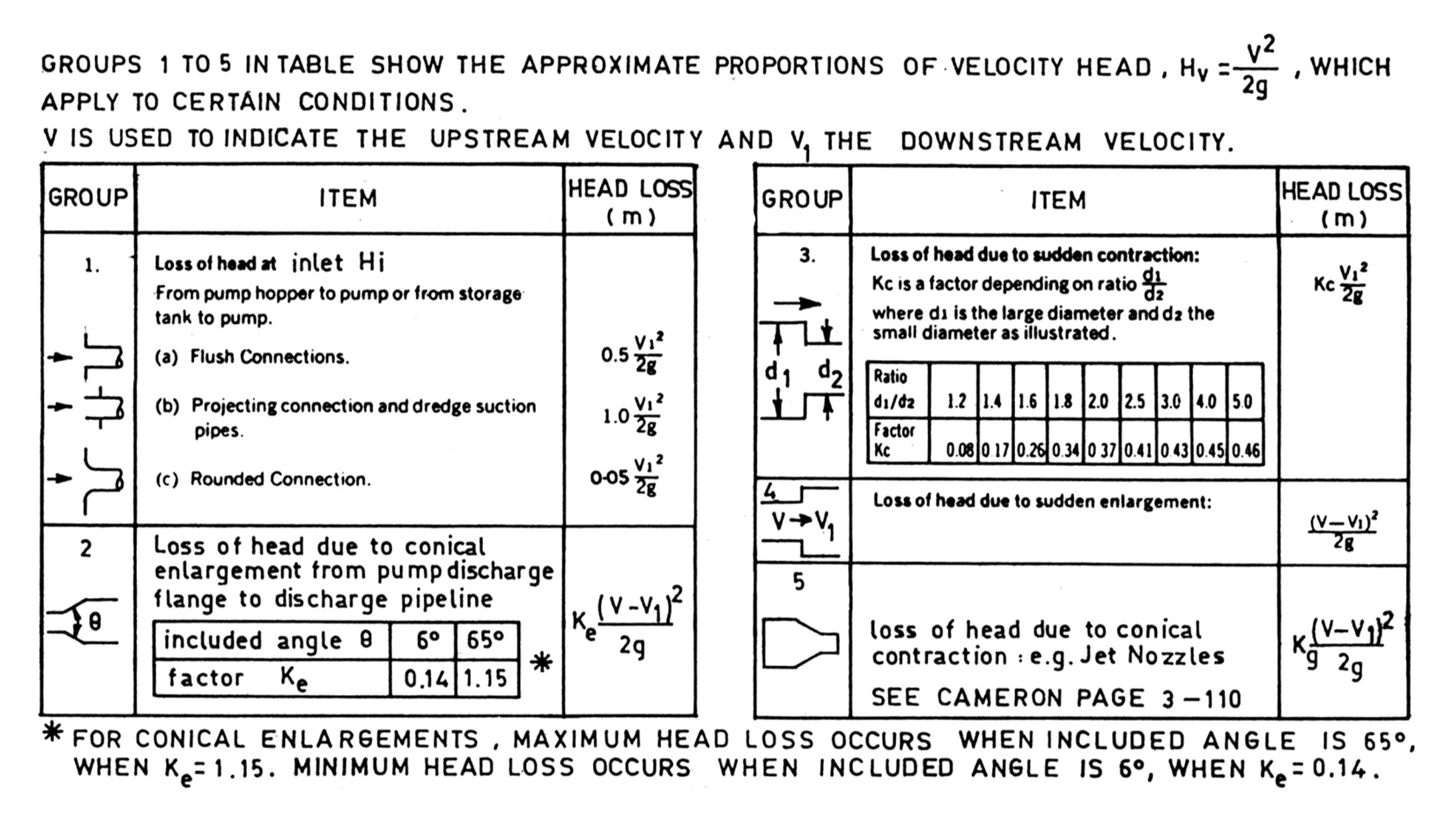

b) Inlet Head Loss, Hi: Exit Velocity Head Loss, Hve

Separate provision is always made in the standard formulae for the terms:

i) Hi, the Inlet Head Loss (Suction side only), and

ii) Hve, the Exit Velocity Head Loss (Discharge side only).

That is, the terms Hi and Hve are included in the standard formulae for Hs and Hd respectively.

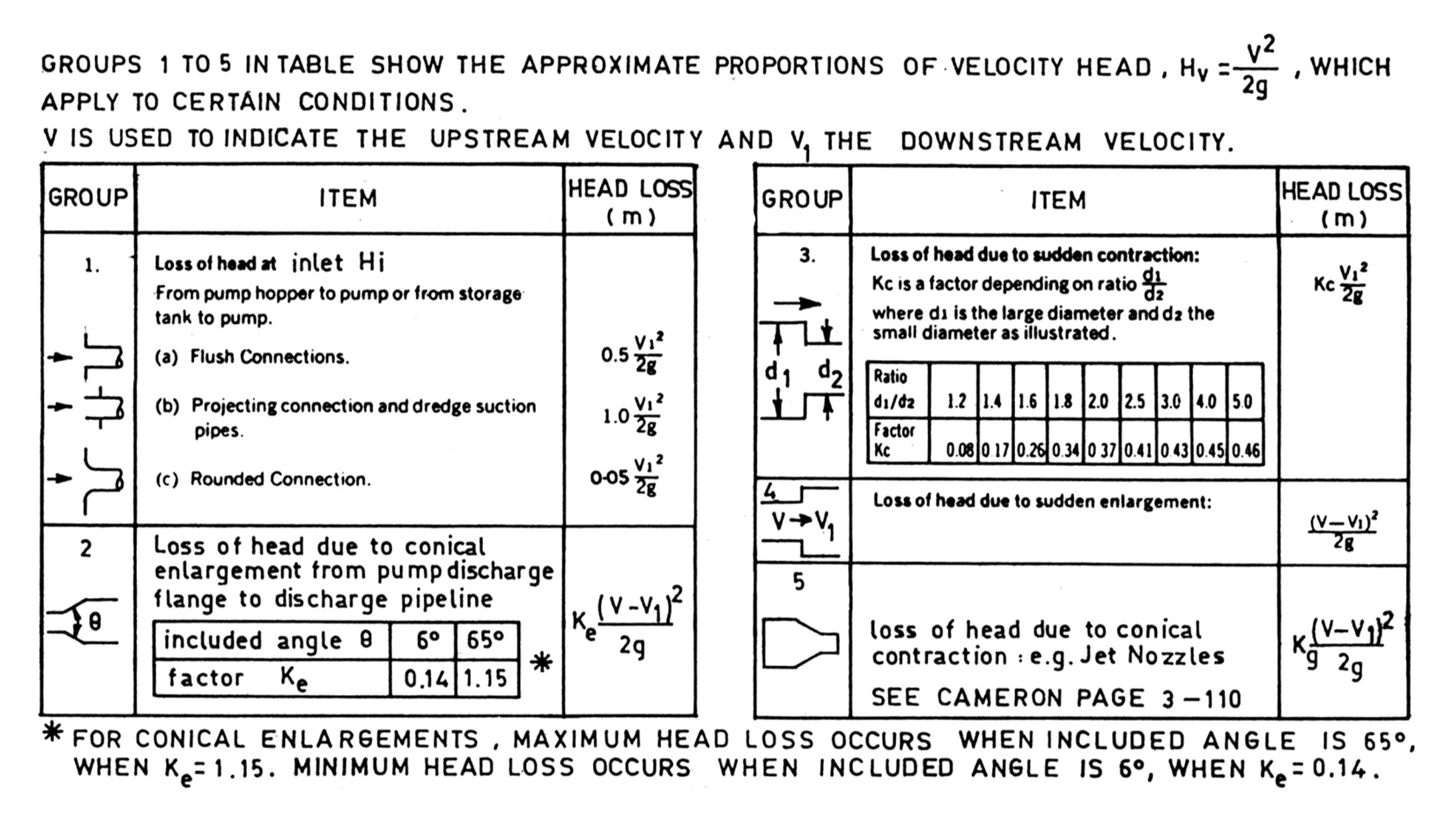

c) Head Losses due to Contractions and Enlargements

These additional head losses are calculated by use of the formulae provided in Figure A4-4. As no separate provisions are made in the standard Hs and Hd formulae for individual symbols or terms anticipating these friction head losses, any such estimated head losses, if applicable, should properly be added to the values calculated for Hfs or Hfd respectively.

Friction losses in jet nozzles (Hn) may be treated as for conical contractions unless more reliable head loss data is available.

FIGURE A4-4 HEAD LOSSES AT INLET, CONTRACTION AND ENLARGEMENT

d) Sundry Additional Causes of Effects on Hfs or Hfd

The calculated values for Hfs and Hfd must be corrected to allow for permanent friction head losses when any in-line restrictions, such as flowmeasuring devices, are intended to be installed (for example, quarter-circle orifice plates).

e) Differential Column Head Loss

Figure A4-5 depicts a mixture of Specific Gravity, Sm, flowing upwards and drawn from a supply of settled solids and overlying liquid, Sl. As the liquid of the same vertical height, Zl. The resulting effective static head loss is known as the differential Column Head loss, Zc:

Sm is greater than Sl, the vertical height Zl, of mixture in the submerged portion of the suction pipe is not completely balanced by the surrounding

Where this condition exists, Zc must be included as an additional head loss in the pipe system. This would effect both total head and NPSHa (refer to APPENDIX 6 – NET POSITIVE SUCTION HEAD (NPSH)).

FIGURE A4-5 DIFFERENTIAL COLUMN HEAD LOSS

sales@mineco.vn

sales@mineco.vn