PHOSPHATE FLOTATION

The BASF product portfolio aims to optimize the performance of both the inverse carbonate and direct apatite flotation, improving the phosphate recovery and grade while minimizing the reagent consumption.

| Decreasing grades of phosphate ores feedstock drives a search for new technologies to maintain beneficiation costs at acceptable level.

Strengthening environmental legislation in many countries is also imposing restrictions on usage of many chemical reagents, necessitating a “greener” replacement. As an example of successful introduction of “green” solutions, a range of biodegradable, low toxicity products replacing the alkylphenol ethoxylate (APEO) surfactants, which were developed by BASF |

|

PRODUCT RANGE

The Lupromin® FP A anionic collectors range is recommended for apatite flotation where the percentage of silicates or calcium oxide / phosphorous pentoxide ratio is high.

Lupromin® FP A 711 is an anionic collector recommended for apatite flotation where the percentage of silicates or calcium oxide / phosphorous pentoxide ratio is high. These products ensure the necessary hydrophilic / lipophilic balance for effective flotation selectivity. The combination of the foaming power of the Lupromin® FP A 711 and its chemistry promotes the necessary selectivity for the flotation process. Collector is supplied as a viscous liquid at room temperature.

Lupromin® FP A 212 is a fatty acid based collector applied for oxidized phosphate ore flotation. The formula of Lupromin® FP A 212 provides high selectivity and metallurgical recovery at lower dosage in comparison with typical vegetal collectors.

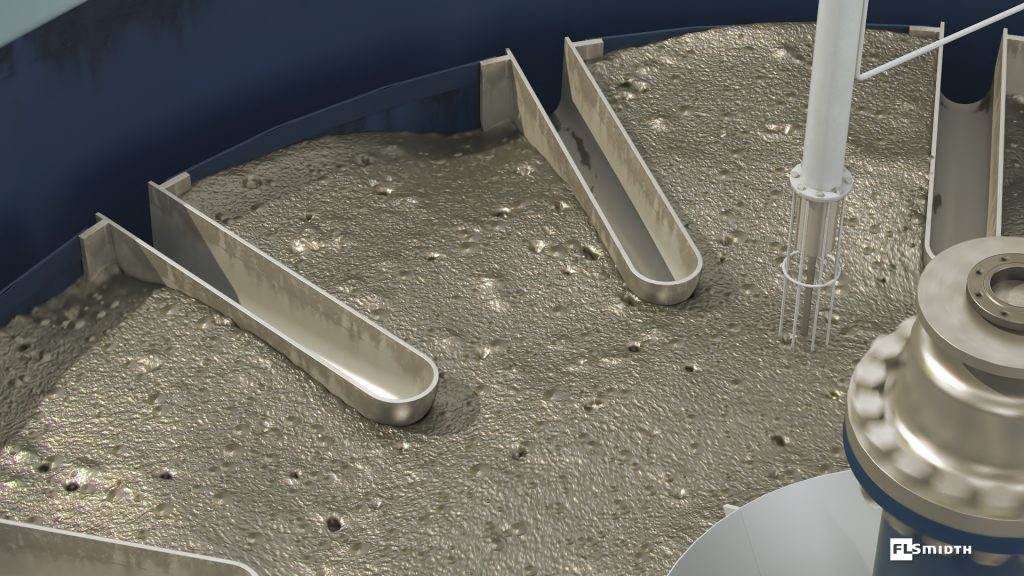

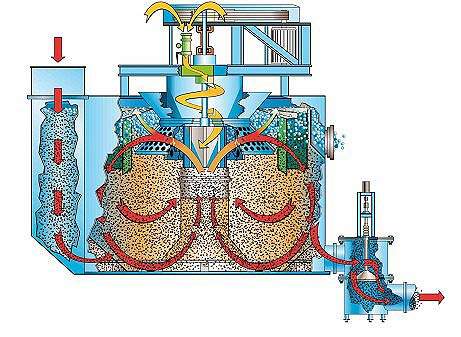

FLOTATION REAGENTS

BASF’s Mining Solutions business offers a diverse range of chemicals and technologies for mineral processing to improve process efficiencies and aid the economical extraction of valuable resources.

We offer our products and technology solutions to the global mineral processing industry along with expert advice and technical support. Our global team is driven by a common goal to provide the best sustainable solution to meet our customers’ processing needs. With technical representation in over 100 countries, BASF’s technical support is provided on a global, regional and local basis.

We can provide reagents, equipment, process technologies and expertise, focusing on applications such as flotation, solid liquid separation, solvent extraction, tailings management, grinding, and materials handling.

BASF’s flotation range includes collectors for non-sulfide ores, frothers, dispersants, and modifiers. BASF’s expertise in surfactant chemistry has resulted in a long history of innovation allowing us to provide innovative, sustainable solutions to ensure our customers’ operations run more efficiently by delivering operational and financial benefits.

BASF’s commitment to an innovative mining industry

Innovation is at the heart of BASF’s Mining Solutions business as our aim is to develop novel and innovative chemistries and technologies to effectively meet the evolving challenges that the mining industry continues to face. BASF is committed to working in close collaboration with our customers, academia, and global industry organizations.

BASF’s extensive backward integration into the building blocks of product chemistries for mineral processing enables us to effectively apply our knowledge and chemical experience to develop both conventional and novel chemistries to meet the technical and commercial challenges faced by the industry, both today and in the future.

Our Product Development and Technical Support personnel are located around the globe and are complemented by three BASF Global Competence Centers, based in Tucson (North America), Ludwigshafen (Europe), and Perth (Australia) and supported by Flotation laboratories in Jacarei (Brazil) and Moscow (Russia).

With our chemistry, equipment, process and application technologies, industry experience, and customer commitment, BASF can uniquely package competencies and expert offerings to effectively support the diversity of mineral processing technology developments and process challenges.

With our chemistry, equipment, process and application technologies, industry experience, and customer commitment, BASF can uniquely package competencies and expert offerings to effectively support the diversity of mineral processing technology developments and process challenges.

| Global Leading Manufactures: |  |

sales@mineco.vn

sales@mineco.vn