Wemco Self Aspirating Flotation Cells

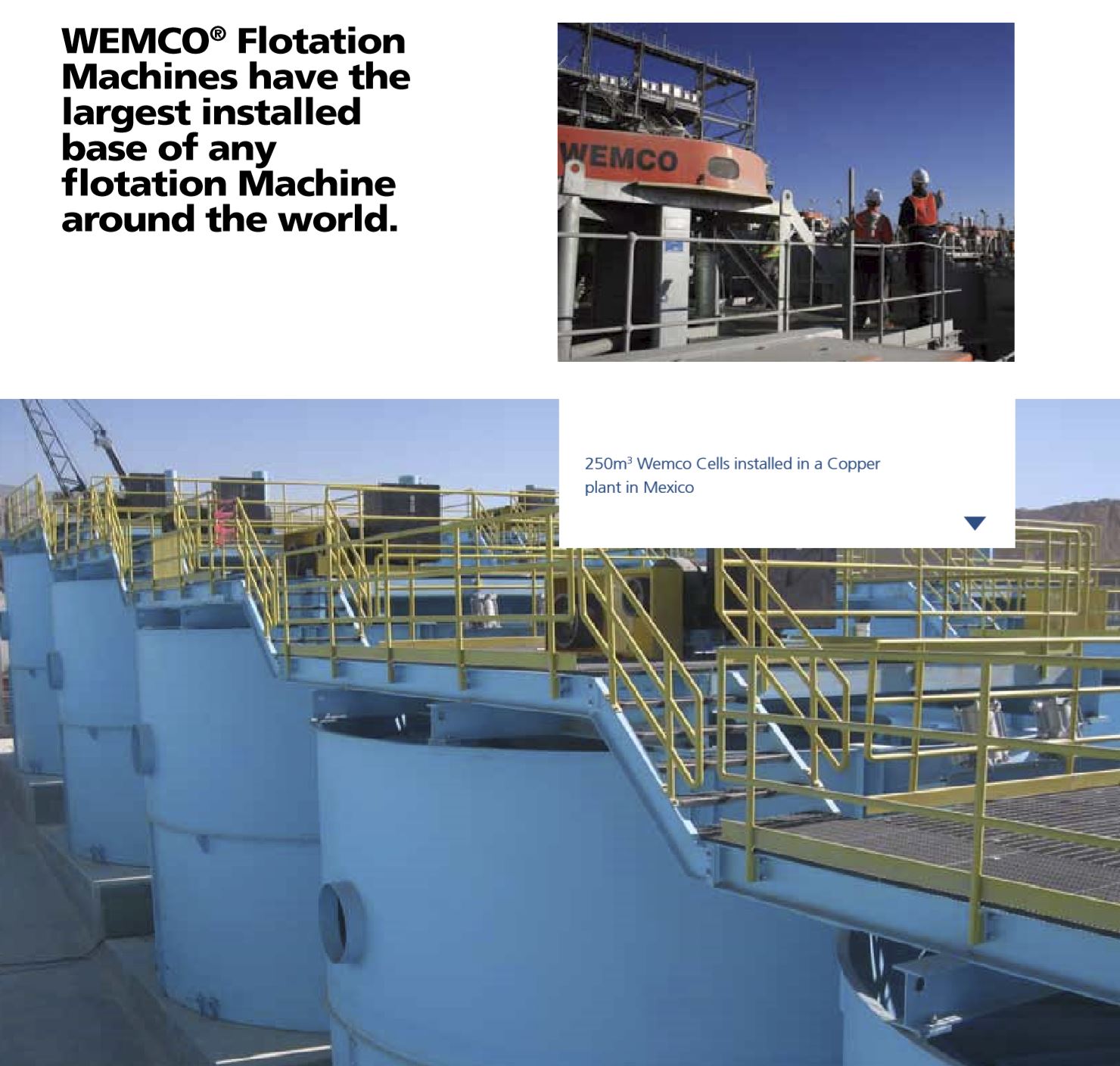

| FLSmidth Minerals is the World Leader in Large Cell Technology with the Greatest Installed Capacity of any Flotation Manufacturer.

FLSmidth Dorr-Oliver Eimco pioneered the way for large cell technology. From its first Wemco 257m3 cell installed in 2003, to now even bigger 300m3 cells being installed in Chile. These 26 x 300m3 Wemco cells will be the first major installation of 300’s for a new plant and the first used in rougher/ scavenger duty! Large Flotation Cell Benefits Results exceed metallurgical, hydrodynamic, and mechanical performance of smaller cells The Wemco SmartCell Flotation machine is available is sizes up to 500m3 to accommodate the largest mining operations in the world. |

|

ADVANTAGES TECHNOLOGY

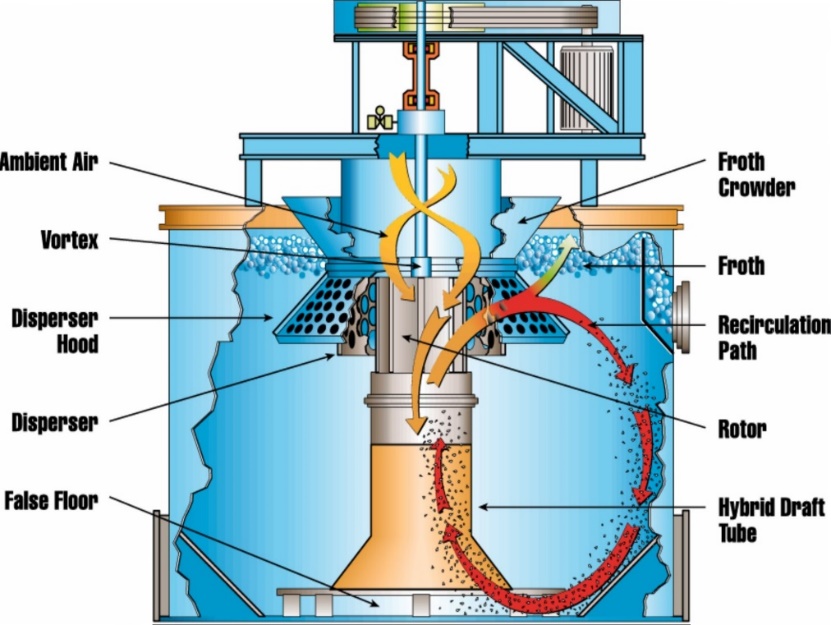

The self aspirating Wemco flotation technology: whether incorporated into the original 1+1™ Flotation Machine design or newer generation SmartCell™ Flotation Cell combines ease of operation with improved metallurgical performance. The Wemco rotor is positioned higher in the flotation tank resulting in the following advantages:

| • Shorter froth travel distance for improved coarse particle recovery

• Reduced maintenance and greater availability » Rotor is positioned near the top of the cell resulting in less wear » Reversing and inverting rotor extends life » Mechanisms can be changed without shutting down or draining the row of cells • No blower and associated air piping is required. |

|

Wemco® SmartCell™ Flotation Machines

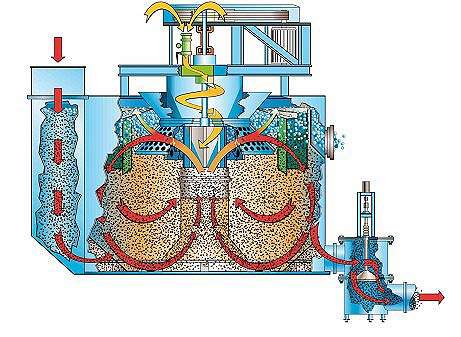

Wemco self aspirating flotation technology has been the industry standard for decades. It has been updated, adapted, and refined into the SmartCell to meet the demands of modern, large scale concentrators.

The SmartCell features large, cylindrically shaped tanks with special design features that improve mixing and achieve unmatched hydrodynamics and tank utilization.

| Since its introduction in 1996, most of the major mineral concentrators have selected the SmartCell to ensure high recovery and ease of operation.

FLSmidth Research and Development efforts have designed the SmartCell to exceed our mineral processing customer’s expectations by using special design features: |

|

- Streamlined hybrid draft tube to optimize slurry pumping

- Beveled tank bottom to eliminate stagnant zones and improve particle suspension

- Tank Baffles to stabilize froth surface and enhance mixing

- Radial Launders to improve froth removal and increase recoveries

The Wemco SmartCell Flotation machine is available is sizes up to 500m3 to accommodate the largest mining operations in the world.

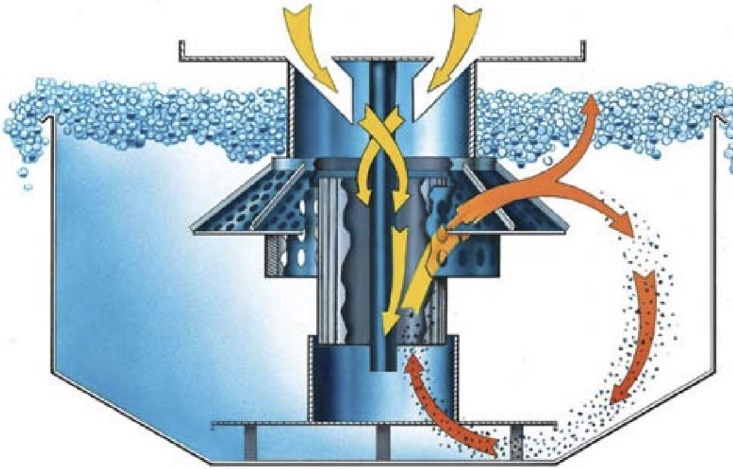

Wemco 1+1™ Flotation Machines

In applications with lower tonnage throughput, traditional rectangular shaped tanks may be the most economical selection. For these applications FLSmidth offers Wemco 1+1™ self aspirating technology.

|

|

MAJOR FLOTATION APPLICATION

- Minerals industrial: Phophate, Potash, Clays, Coal

- Base Metals: Iron, Copper, Lead, Zinc

- Preciuos Metals: Gold, Platinum and Palladium, Silver, Nickel

- Industrial Processing

- Waste Water Treament

| Global Leading Manufactures: |

|

sales@mineco.vn

sales@mineco.vn