Improving flotation efficiency, Innovation in flotation

You need to make sure that your design criteria meet the specific demands of your mine. Yet, bottlenecks still occur, and undersized dewatering circuits are extremely unforgiving. So how can you make a flotation device more efficient without making it consume more energy? Our flotation team was pretty sure that they could improve the energy efficiency of flotation by rethinking the rotor/stator technology. It just required a change in the hydrodynamics of the flotation system.

Reduce energy consumption, improve performance

The answer they came up with was the nextSTEP™ rotor/stator. But the longer story about how that technology was developed shows how cooperation across industries and academia can help save energy and improve productivity in your mine.

A step change in both metallurgical performance and energy efficiency

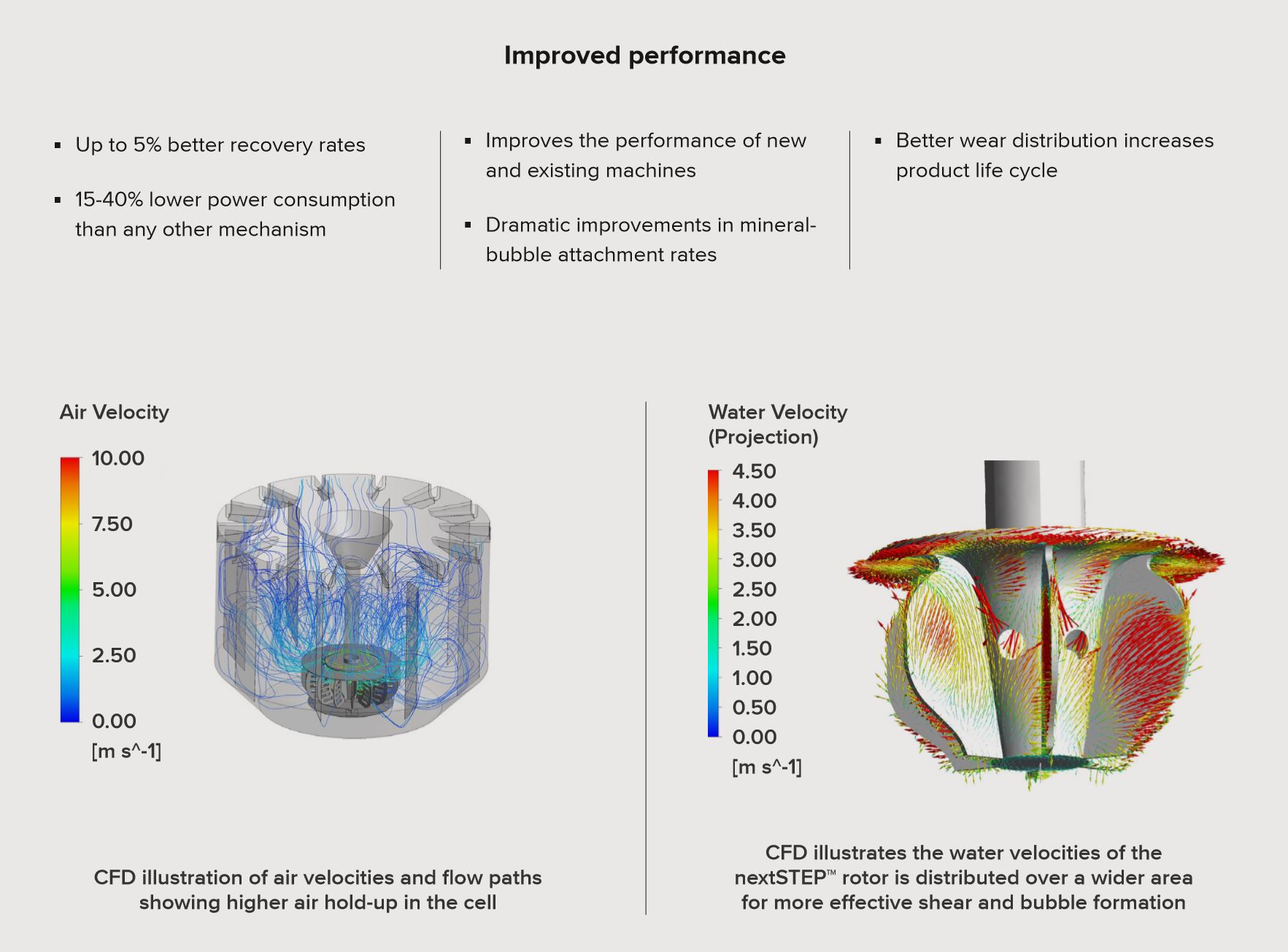

The nextSTEP™ Rotor is designed to produce ideal flow streams. It also produces strong enough turbulence to enhance bubble-particle attachment. This improves recovery rates and concentration grades while lowering energy requirements.

Improved performance

FLSmidth is the world’s largest supplier of flotation equipment offering lower energy consumption, improved recovery and increased operational efficiency.

| For the initial technology developmental phase, we teamed up with aerospace researchers, surface chemistry researchers and the Center for Advanced Separation Technologies at Virginia Tech. The combination of mining industry academics and experts from the aerospace industry allowed the team to come up with an innovative design concept for the rotor/stator.

Smaller bubbles have better attachment properties than large ones. But if you increase the rate to improve throughput, the flotation cells produce larger, not smaller bubbles. So it’s really not a straightforward proposition. The aim was to design a machine that enabled an increase in the the air volume and a reduction in the bubble size at the same time, while optimising the energy dissipation rate. |

|

Saving energy and improving performance

The target was to create a new ultra low-energy flotation system. The team succeeded to the extent that the nextSTEP™ rotor/stator reduces your power requirements by 15-40 percent and has the lowest operating power of any forced-air flotation mechanism on the market.

To create an environment for the bubbles and particles to make contact with the least amount of power possible, the vane of the rotor was elongated and slots were cut in the stator to optimise the geometry of the rotor/stator assembly.

The design also improves your performance. The new rotor produces ideal flow streams and an energy dissipation rate that enhances the bubble-particle attachment. The patented rotor/stator makes energy dissipation more uniform which results in a higher probability of bubble to particle contact during the flotation process. This dramatically improves your attachment rates.

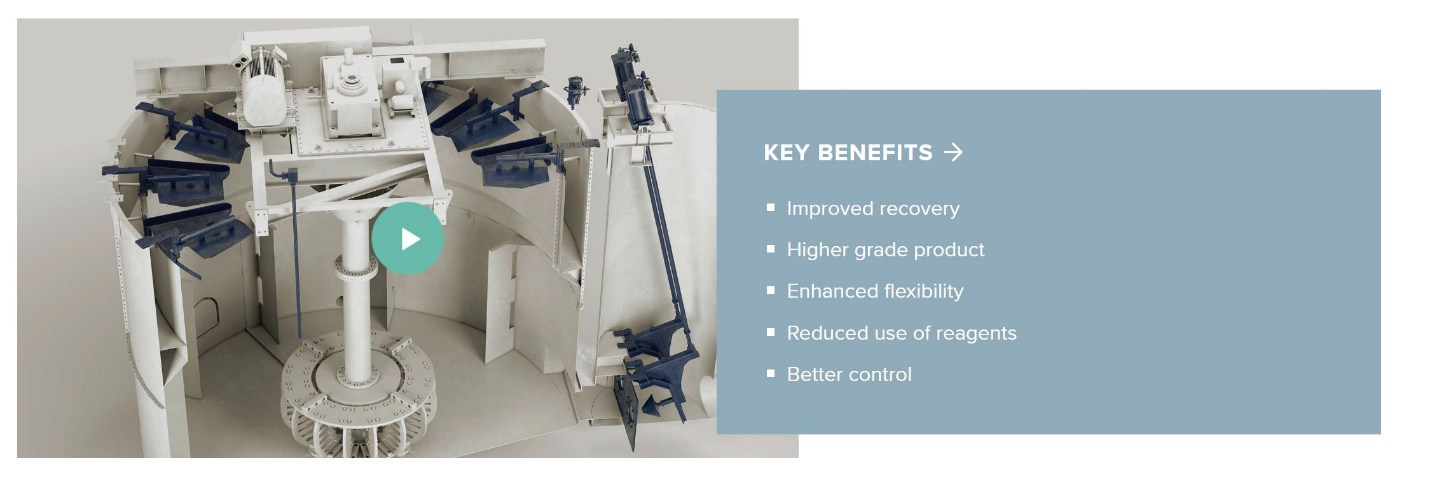

Froth Recovery Upgrade Package

Improve metallurgical performance with advanced froth phase control

Enjoy superior froth-level control and metallurgical performance, with the FLSmidth Froth Recovery Package. Take your flotation cell to the next level with actuators, level sensors and radial froth crowders designed to provide improved recovery and grade.

Get the most out of froth recovery with our Froth Recovery Package

Often, before you can put your valuable ore to good use for your business, you need to separate it out from the waste material. And in many cases, the answer is froth flotation. However, froth flotation is not an exact science, and small-yet-numerous particles of valuable ore may be getting thrown out with the tails. These can add up, accounting for a significant loss in potential revenue. Our Froth Recovery Package offers a solution that not only improves froth recovery, but also saves overall costs.

The Froth Recovery Package enables you to better control the froth phase, which in turn improves the performance of the flotation cell. The addition of the radial froth crowders adds a new dimension to the control strategy. It allows you to shift the grade recovery curve by allowing either deeper froth or faster froth removal.

Proven technology from experienced Froth Recovery Package manufacturer

|

|

|

Global Leading Manufacture:

sales@mineco.vn

sales@mineco.vn