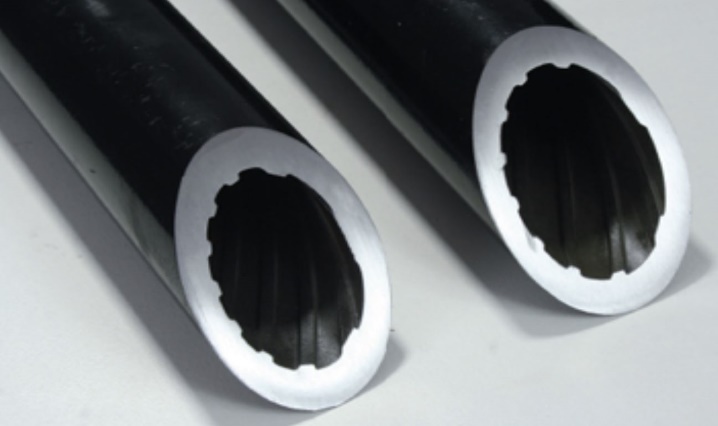

BOILER TUBES

| XID, or X-ID boiler technology refers to internally augmented boiler tubes that feature helical ribs embossed on the inside of the tube to provide increased surface area and increased heat transfer for gas flowing inside the tube of a firetube boiler. These internal spiral ribs cause a complex boundary layer separation and reattachment phenomenon. The combined depth of tubing wall and ribbing is above minimum wall specifications and delivers a tested inside transfer rate of up to 85% greater than plain tube. |

|

| The design of the tube gives it more “heating surface” than a standard tube and transfers more heat into the water from the hot flue gas as well. Because XID tubes add more heating surface and transfer more heat, they reduce the need for additional heating surface of the overall boiler. This allows a smaller physical foot print, ideal where space is limited. |

|

As X-ID boiler tube technology improves transferring the heat content of the fuel into the boiler water, more heat can be absorbed to the lower the flue gas temperature and produce greater operating efficiency (the ratio of heat output against heat input). Case studies have shown that XID tubes can add additional 4%+ to boiler fuel efficiency.

In addition to greater efficiency, other key benefits include:

■ up to a 20% cost savings over bare tube designs

■ increases steam-volume capacity

■ improves steam quality

■ reduces space requirements (footprint)

■ reduces fuel consumption

■ lowers NOx emissions

ECONOMIZERS

| Economizers (as well as air heaters) perform a key function in providing high overall boiler thermal efficiency by recovering low level (i.e., low temperature) energy from the flue gas. For each 40F (22C) that the flue gas is cooled by an economizer or air heater in a conventional boiler with air as the oxidant and normal excess air, the overall boiler efficiency typically increases by approximately 1%. |

|

| IN-LINE “H” FIN DESIGNS OFFER COUNTLESS BENEFITS

■ Particularly effective in applications with dust-laden flue gas ■ Reduces turbulence and fouling of tubes ■ Typically reduces gas velocities and tube erosion rates |

|

■ Offers the ability to vary fin spacing along the same tube to suit different ash burdens from front to back of the backpass

■ Provides a more compact design with reduced pressure drop versus existing bare tube designs

Material Specifications:

SA178 : Electric resistance welded carbon and carbon manganese steel boiler and superheater tubes

SA179 : Seamless, cold-drawn low carbon steel tubes for tubular heat exchangers and condensers

SA192 : Seamless carbon steel boiler and superheater tubes for high-pressure service

SA209T1A: Seamless carbon-molybdenum alloy steel, boiler and superheater tubes

SA210 : Seamless medium-carbon steel boiler and superheater tubes

SA213 : Seamless ferritic and austenitic steel, boiler and superheater tubes and austenitic steel heat-exchanger tubes

SA214 :Electric resistance welded carbon steel heat exchanger and Condenser Tubes

SA423 : Seamless and electric welded low alloy steel tubes

Dimensions:

■ Length: Straight Tubes up to 10m

■ Diameters of 3/4″ through 4”

| Leading manufacture: |  |

sales@mineco.vn

sales@mineco.vn