COMBINED FLOTATION CELLS

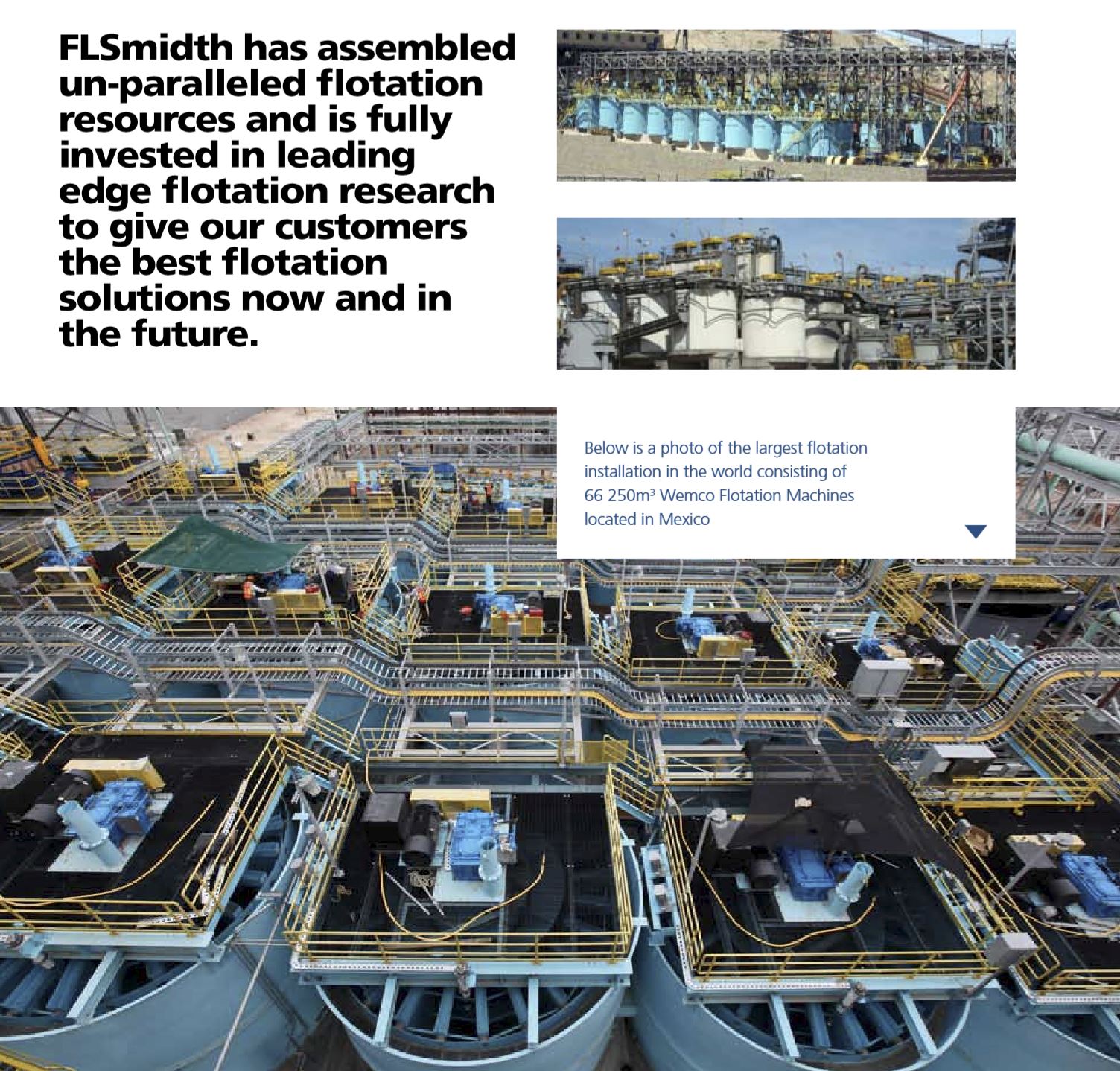

By combining Wemco® self aspirated and Dorr-Oliver® forced air cells in the same plant FLSmidth can exploit their unique characteristics to maximize circuit and row performance.

| In the past, mineral producers had to choose between mechanical flotation systems that naturally ingest ambient air and others that require a blower. FLSmidth is in the unique position to exploit the inherent and unique advantages of both the Wemco® self aspirated and Dorr-Oliver® forced air technologies. These two types of machines can be used in different parts of the flotation circuit forming a Mixed Circuit™ or in a single row forming a Mixed Row™. |

|

Mixed Circuits™:

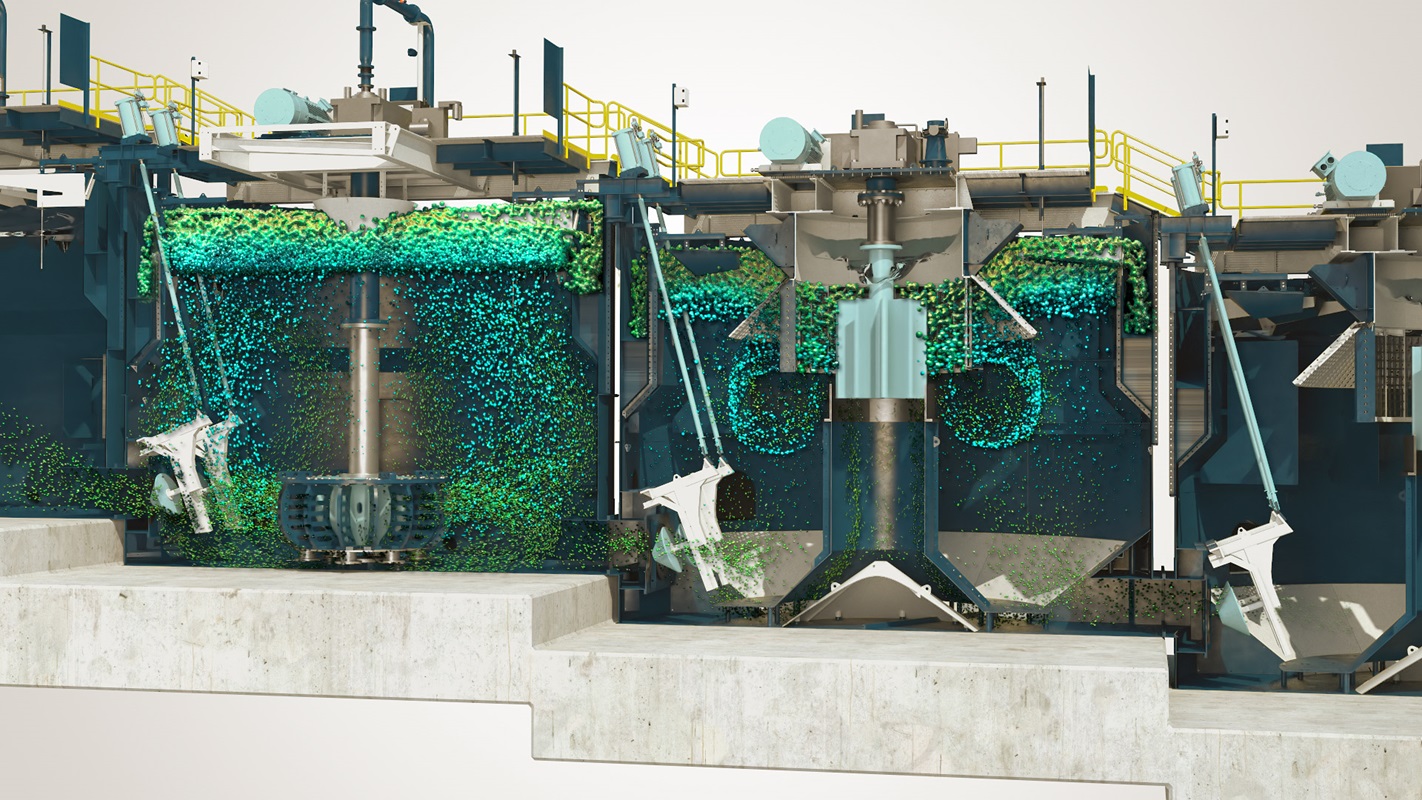

Wemco for Recovery & Dorr-Oliver for Cleaners The Wemco design with its agitator near the top of the tank maximizes coarse particle recovery since transport distance of the fragile bubble particle aggregate is minimized. The Wemco mechanism is also not exposed to the damaging effects of tramp material (ball chips etc) that are inevitable in rougher circuits due to upsets. The Wemco cell is a true workhorse for rougher, rougher scavenger and cleaner scavenger applications.

The Dorr-Oliver design with its rotor/stator at the bottom of the tank is well suited for maximizing air dispersion and focusing energy dissipation, conditions which drive fine particle flotation. The fine particles can survive the higher transport distances inherent in this design. This distance also serves to promote upgrading making the Dorr-Oliver machine ideally suited for cleaner applications. Air control and higher range of froth depth with the Dorr-Oliver design also are beneficial in the cleaner application. The FLSmidth Mixed Circuit™ is an exceptional and unique flotation solution to optimize your flotation plant performance.

Mixed Rows™:

Maximizing recovery by combining Wemco and Dorr-Oliver Mechanisms in the Same Row The Mixed Row is an extension of the Mixed Circuit concept. By combining the inherently different designs in the same row it is possible to exploit their unique advantages further to maximize recovery. There are several strategies which have been employed in several plants around the world. These are tailored to the particular application and can offer greatest flexibility for optimized recovery.

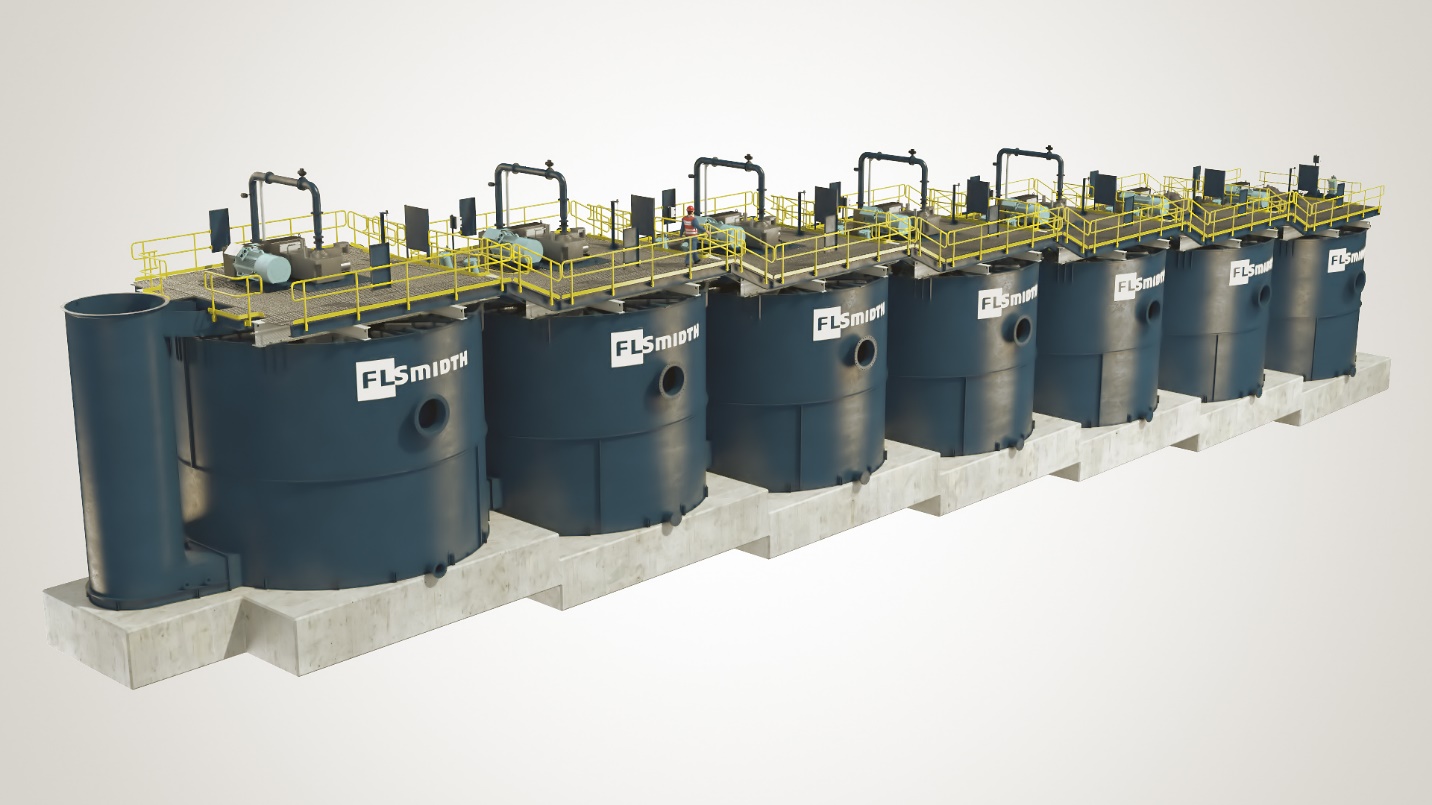

The Universal Tank

On large cells (100m3 and larger), we have developed a “Universal Tank” that can accommodate either the Wemco induced-air cell or the Dorr-Oliver forced-air cell and are interchangeable to provide flexibility for future ore changes or other considerations. By supplying customized solutions to its mineral processing partners, FLSmidth maintains its global industry leadership in the supply of flotation technology with over 53,000 flotation cells delivered to date.

MAJOR FLOTATION APPLICATION

- Minerals industrial: Phophate, Potash, Clays, Coal

- Base Metals: Iron, Copper, Lead, Zinc

- Preciuos Metals: Gold, Platinum and Palladium, Silver, Nickel

- Industrial Processing

- Waste Water Treament

| Global Leading Manufactures: |

|

sales@mineco.vn

sales@mineco.vn