micMAX™ – PERFECT SLURRY PUMP FOR MOST ABRASIVE SLURRIES

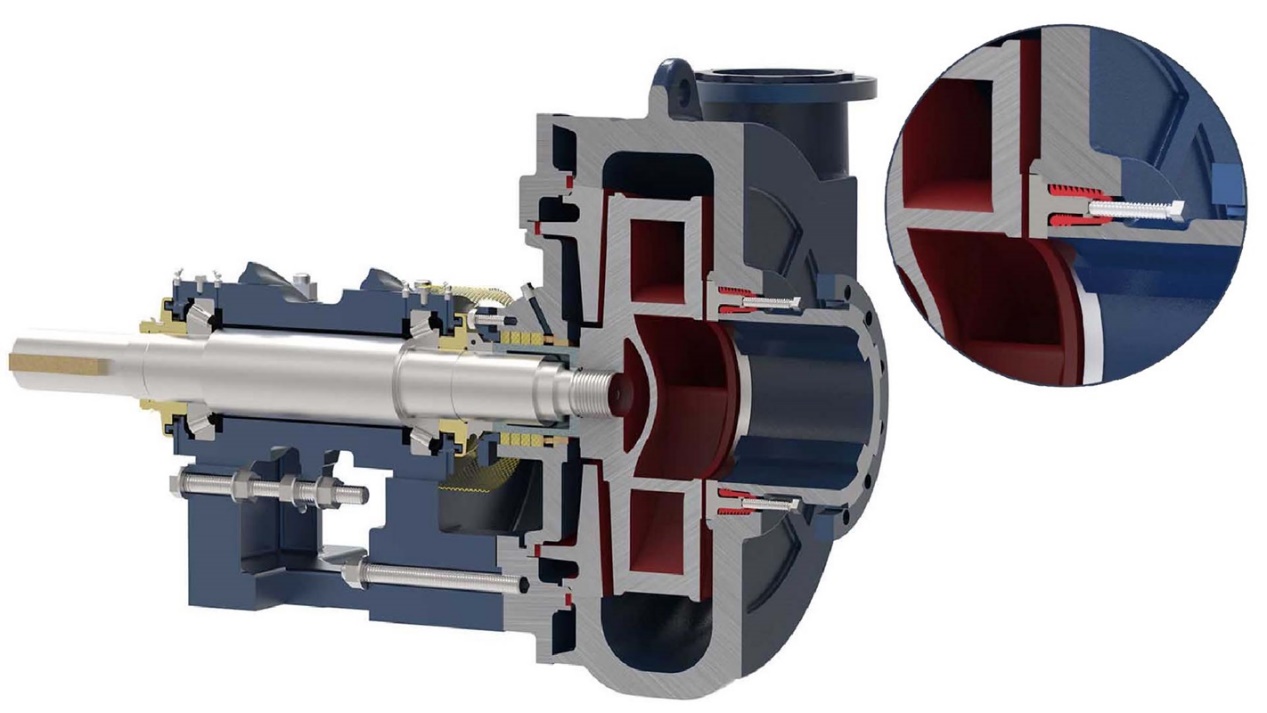

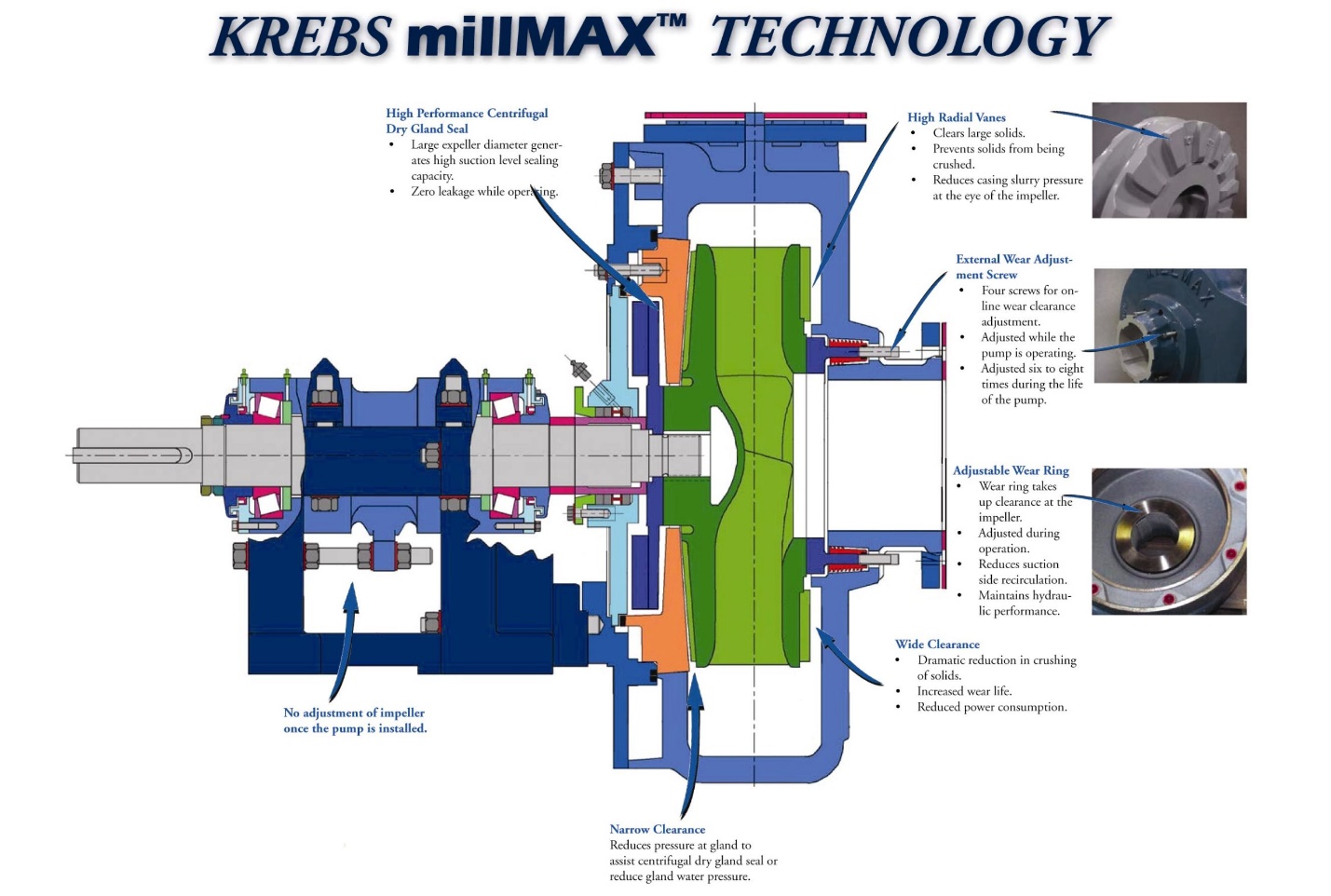

| micMAX™ severe-duty slurry pumps have a unique design developed for grinding mill discharge duties and other abrasive slurries.

Mineco offers wet end conversions or complete pump assemblies to meet customer desires and demands. The micMAX™ pump features a patented on-line wear clearance adjustment, which minimizes cost per ton pumped compared to conventional hard metal and rubber lined pumps through:

|

|

The key advantage of our slurry pumps is the 10% to 30% lower power, long even wear life and less pump downtime, which results in lower cost-per-ton pumped, along with better cyclone separation.

HEART OF DESIGN

- CASING – designed for minimum slurry turbulence and even wear. Includes (14×12 and smaller) integral wear ring, carrier, and adjustment screws for on-line adjustment and elimination of suction side recirculation.

- WEAR RING – adjustable wear ring assembly to permit closing of suction side impeller clearance during operation. This reduces slurry recirculation and lowers pressure at the suction area, thereby maintaining flow and reducing wear.

- IMPELLER – designed for high slurry efficiency and hydraulic performance. Machined surface at the eye for wear ring adjustment and high expelling vanes.

- BACKLINER – designed for close clearance at the back (14×12 and smaller), or SUCTION LINER with integral wear ring (16×14 and larger). Matching full impeller diameter and profile for close operating clearance.

- WEAR PARTS – designed hydraulically to wear evenly. Constructed of high chrome at 680/720 Brinell hardness.

- POWER FRAME – heavy duty cast iron pedestal with external bearing assembly adjustment mechanism. Drilled for overhead motor mounting assembly.

- FLANGES – loose intake and discharge flanges drilled to suit various pipe requirements.

- BEARING ASSEMBLY – heavy duty shaft and indirect fitted taper roller bearings rated at 100,000 hrs B-10 life minimum. Bearing arrangement designed to prevent over greasing and ingress of slurry.

THE KEY ADVANTAGE TECHNOLOGY:

ceralMAX™ – PUMP DESIGNED FOR ABRASIVE SLURRIES WITH LARGE SOLIDS

Efficient pumping in aggressive applications

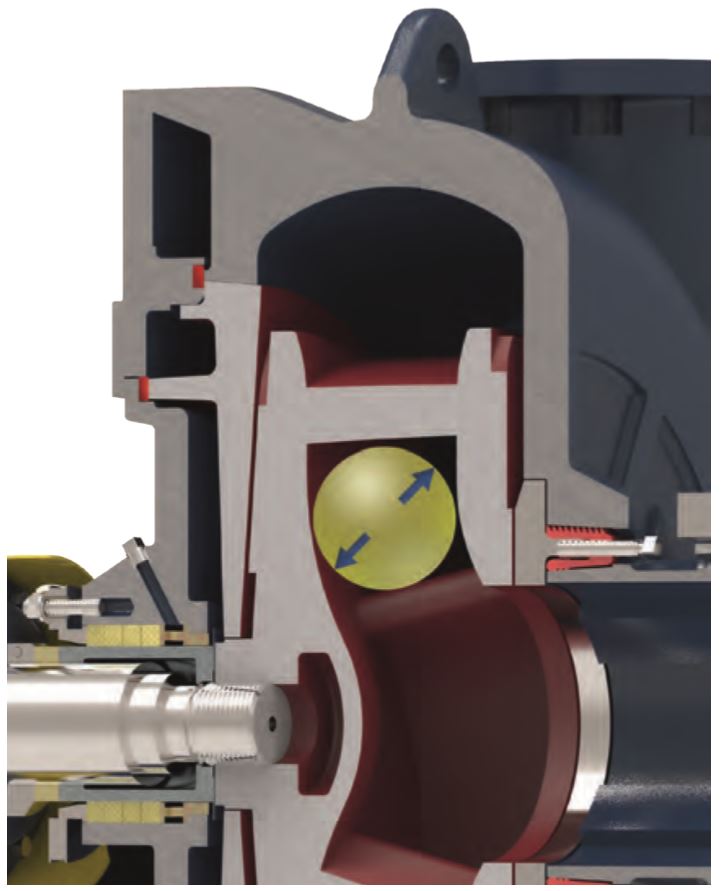

| Why sacrifice wear life to pump the largest solids and most abrasive slurries? This is the question we asked which lead to the development our heavy-duty ceraMAX pump. With large internal clearances and a wide impeller, our ceraMAX presents the ideal solution to optimise passing size, efficiency and wear life. |  |

ceraMAX™ benefits of our optimized design

Many slurry pump applications in coal, dredging and hard rock mining require the ability to pump large solids. Traditionally, operations used open impellers or extremely oversized pumps to get the job done – at the cost of ineffective performance. Our ceraMAX is designed for high efficiency, and long wear life and tackles the most abrasive slurries.

| Pumps large and abrasive solids

A wide diameter impeller and increased cutwater clearance allows for the passing of large solids. The addition of the wear ring feature provides a large clearance between the impeller and suction side to ensure solids are not ground up in the pump as they would be with conventional designs. |

|

Design options to maximize solids passing size

|

|

|

| ceraMAX pump in a heavy duty wide diameter impeller | ceraMAX pump handles a wide range of solids sizes up to 8″ top size. |

DRIVE ARRANGEMENTS

|

|

| Overhead on top | Reverse overhead |

|

|

| Side by side | Direct inline |

APPLICATIONS

|

|

sales@mineco.vn

sales@mineco.vn