duraMAX™ PERFECT SLURRY PUMP FOR HIGH HEAD APPLICATIONS

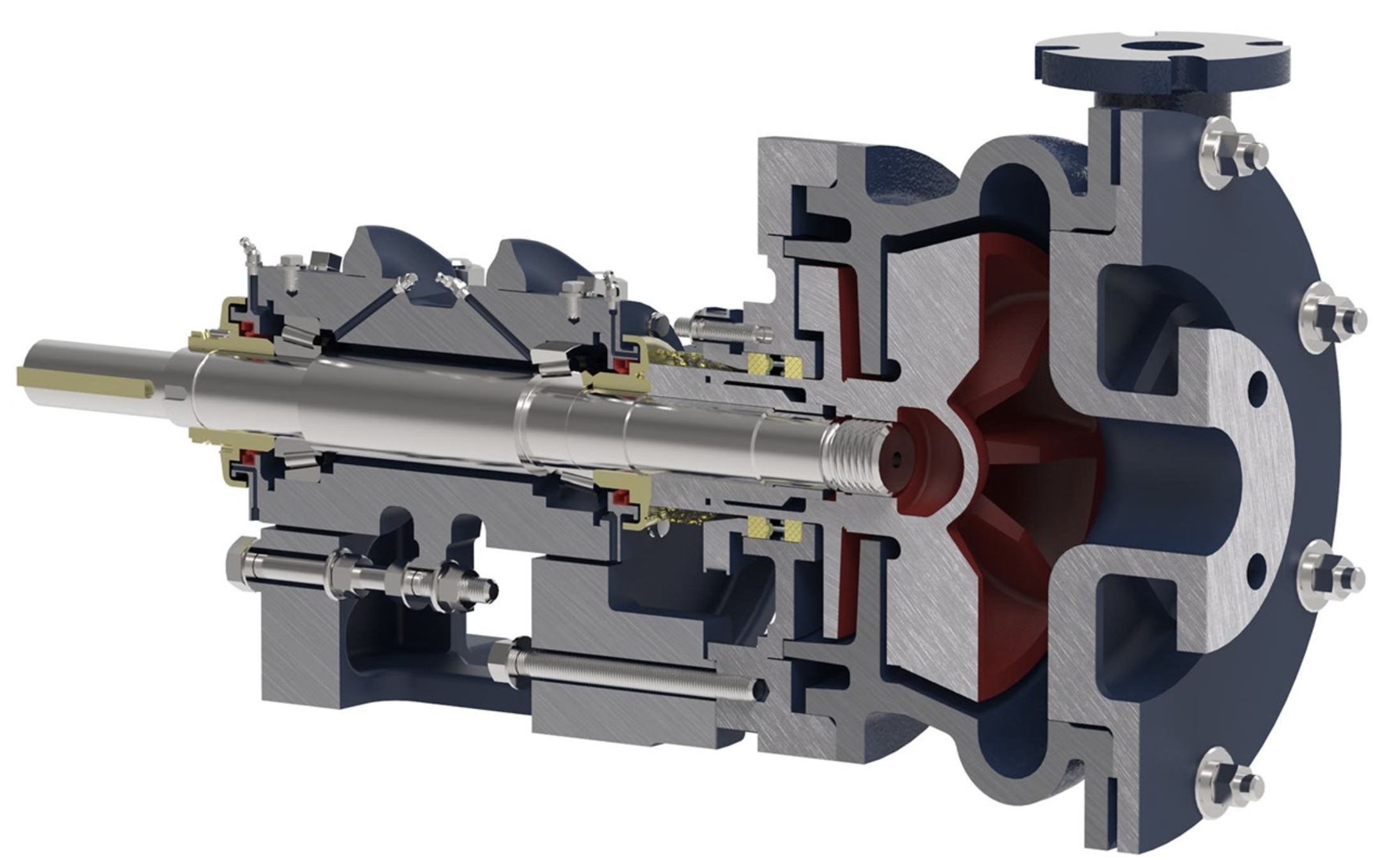

| duraMAX centrifugal slurry pump to provide clear passage of large solids, and to minimise shearing, solids degradation, air locking and wear.

Our duraMAX pump, with its large internal clearances and superior hydraulic design, maintains the integrity of the product by delicately handling solids in suspension. The duraMAX reduces carbon attrition and shear stress making it an ideal choice for the carbon transfer process. Suitable for all industries where tramp material, product degradation, and entrained air can affect pump performance. |

|

In applications such as flotation, concentrate slurries will have a significant amount of entrained air known as froth. When pumping froth slurry, special considerations must be taken since it will no longer perform as normal slurry at the same pump speed.

In applications such as flotation, concentrate slurries will have a significant amount of entrained air known as froth. When pumping froth slurry, special considerations must be taken since it will no longer perform as normal slurry at the same pump speed.

The difference is due to the air, which expands in the low-pressure zone at the eye of the impeller and inhibits the flow going through the pump. Traditionally, pumps are oversized to account for the volume of air at the eye of the impeller so that they still generate the required flow rate.

Oversizing, however, is not the only solution! With a recessed impeller design, the duraMAX allows for the clear passage of air entrained slurries without influencing the duty flow and head. Through constant recirculation, the open vortex impeller design allows for froth advancement without air locking. In fact, the duraMAX can handle slurries containing up to 30% entrained air.

PRODUCT FEATURES

Unique features drive the duraMAX pump’s powerful performance

The duraMAX centrifugal slurry pump is designed to provide safe passage of large solids without clogging and without shearing or degrading the product. Even at low flows, the duraMAX provides performance that cannot be reached by many centrifugal pumps.

Our duraMAX pump is the longest-wearing and most efficient pump in its class. It features a heavy-duty concentric casing design that reduces radial loads and extends bearing life. The recessed impeller and concentric casing provide large internal clearances that allow for the clear passage of large solids and reliable operation at low flows.

Our duraMAX pump is available in sizes ranging from 80 mm x 50 mm (3-inch x 2-inch) to 250 mm x 200 mm (10-inch x 8-inch).

KEY BENEFITS

The duraMAX preserves your product and prevents air locking

Minimized product degradation and shearing

The duraMAX’s concentric casing and recessed impeller design create large internal clearances that allow for clear passage of solids without contacting the impeller – reducing the chance of product degradation and shearing.

| Reduced risk of air locking

The duraMAX is designed to reliably pump slurries with up to 30% entrained air without air locking. Through constant recirculation, the bubble at the impeller eye is broken up, increasing efficiency, reducing power draw and minimising flow instability, even in flotation applications and low-level sump operations. |

|

Large solids passing size

The duraMAX is designed to provide safe passage of large, shear-sensitive solids without clogging and without degrading the product.

Extended wear life

The heavy-duty concentric casing design eliminates radial loads, which greatly extends the life of the pump, the seals and the bearings.

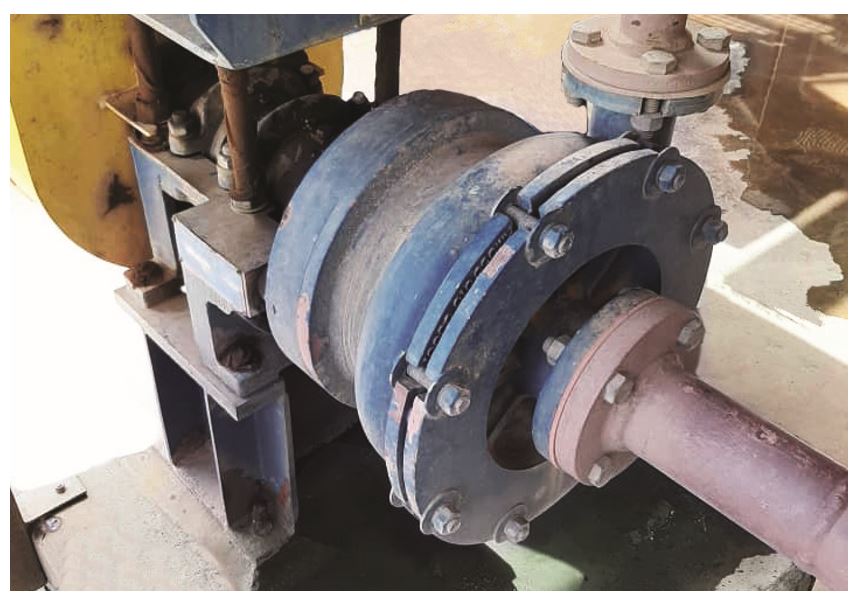

DRIVE ARRANGEMENTS

|

|

| Overhead on top | Reverse overhead |

|

|

| Side by side | Direct inline |

APPLICATIONS

- Mining industrial

- Mineral ore: Apatite, Gold, Copper, Titanium, Nickel, Iron, Alumilium, Sand and gravel, Ash and slag,…

- Processing SAG mill discharge

- Cyclone feed

- Tailings

- Mill discharge

- Industrial processing

- Heavy-duty abrasive slurrie

sales@mineco.vn

sales@mineco.vn